12kv/24kv/35kv/38kv/40.5kv配电网固体开关柜全绝缘全密封看门狗分界开关柜开闭所NKVSR3

推荐应用使用领域

低温寒冷地区:无SF6气体应用.无需考虑SF6气体低温运行问题.在-45°C下也能正常运行。(SF6在超低温下绝缘水平下降)

高原地区:无需考虑高原大气压对绝缘性能的影响。(例如高原地区新疆、西藏、青海、甘肃、内蒙古、云南、贵州、四川)

强风沙地区:密体绝缘环网柜本体安全防护等级IP67.控制回路室采用特殊处理确保强风沙地区长期运行。(例如内蒙古、宁夏、新疆、青海、西藏、河北等地)

沿海潮湿地区:环氧树脂密封.抗潮湿.抗盐雾腐蚀.确保在沿海地区能长期使用。(不需要加热器,不怕浸水)(例如广东、广西、福建、浙江、上海、江苏)

可配置手机app测控/智能短信控制/无线控制分合/远距离遥控分合/国能控制/安全控制/

GPRS/101/104/后台智能控制/智能分界开关箱/分支箱

DTU/FTU/RTU测控智能开闭所/用户分界落地箱式开关柜

配网看门狗分界开关在10kV 24kV 35kV 38kV线路上的应用可大大减少无故障线路的连带性事故停电、缩小故障停电范围、缩短用户停电时间,从而提高用户的供电可靠性。

分界断路器/负荷开关是将断路器/负荷开关和分界保护测控装置,以及通讯模块融为一体的装置,可随配电网络配置、体积小、投资少,它的应用对提高配电网的安全可靠性,保证电网的安全运行具有重要意义。

我公司的分界开关其主要功能:运行中自动隔离用户侧相间短路故障、自动切除用户侧接地故障,并可用于操作拉合负荷电流。

分界负荷开关带有一套内置电压互感器、一套内置电流互感器;有CPU内部处理器和通讯模块;故障跳闸时带有电压判断和故障记忆;具备跳闸闭锁功能。

分界负荷开关适用于10 kV 24kV 35kV 38kV 中性点不接地、经消弧线圈接地或经低电阻接地系统的配电线路与用户(含临时用户)的分界。

2.2 主要作用

2.2.1 自动切除单相接地故障

当用户支线发生单相接地故障时,分界开关自动分闸,甩掉故障支线,保证变电站及馈线上的其它分支用户安全运行。

2.2.2 自动隔离相间短路故障

当用户支线发生相间短路故障时,分界负荷开关在变电站出线保护跳闸后,立即分闸甩掉故障线路。变电站出线开关重合后,故障线路被隔离,使馈线上的其它分支用户迅速恢复供电。

2.2.3 快速定位故障点

用户支线故障造成分界开关动作后,仅责任用户停电,并可主动上报故障信息,使电力公司能迅速明确事故点,及时进行现场处理,使故障线路尽早恢复供电。

2.2.4 监控用户负荷

分界负荷开关可将检测数据传送电力管理中心,实现对远方负荷的实时监控。

2.3 分界负荷开关的故障处理方式

分界负荷开关的故障处理方式见表2。

| |

系统接地方式 |

故障点保护处理 |

| 单相接地故障 |

中性点不接地系统用户界内 |

判定为永久接地后立即跳闸 |

| 中性点经消弧线圈接地用户界内 |

| 中性点经小电阻接地用户界内 |

先于变电站保护动作跳闸 |

| 中性点不接地系统用户界外 |

不动作 |

| 中性点经消弧线圈接地用户界外 |

| 中性点经小电阻接地用户界外 |

| 相间短路故障处理 |

用户界内

|

电源侧断路器跳闸停电后,分界负荷开关分闸 |

|

用户界外

|

不动作 |

固体全绝缘全密封智能分界开关柜NKGT-12/24/35本体部分介绍

NKGTXGN15-12/24/35箱型固定式交流固体绝缘金属封闭开关设备

( 二) .1概述

NKGTXGN15-12/24/35箱型固定式交流固体绝缘金属封闭开关设备

(简称”固体环网柜)是具有高可靠性的免维护小型化开关柜,

产品适用于三相交流50/60Hz,电压为3-12/24/35KV环网供电或辐射供电系统。

固体绝缘环网柜NKGTXGN15 是新一代环保型复合绝掾环网柜。是一种全密封的供电单元,所有带电部件及开关全密封在一个环氧树脂壳体内,壳体内无SF6气体。整个开关装置不受外部环境影响,确保运行可靠性和人身安全性,并且实现了免维护。

固体绝缘环网柜有三种开关组成,即V单元(断路器单元),C单元(负荷开关单元).F单元(组合电器单元),每个单元可以单独使用也可以自由扩展,其结构分为智能控制仪表室、操作机构和一次部分,仪表室可配微机保护(控制器), 一次部分采用APG自动凝胶工艺,将隔离开关和灭弧室完全固封在环氧树脂中,并有专用接头和母线相连。灭弧室采用专用 的铜铬触头材料,R型纵磁场触头,以及完全一次封排工艺.该灭孤室开断短路电流能力及稳定性、电寿命、温升以及绝缘水 平都较之前的灭孤室(铜铝触头材料),杯状纵磁场触头结构,以及不完全一次封排工艺有了明显提高。操动机构采用与开 关配合一体的弹操机构,即隔离开关和主开关弹操机构为一整体,可方便实现互锁,而且机构零件少,减少了不必要的传动 环节,可靠性高,并可根据用户需要实现电动操作。

固体绝缘全封闭开关设备:是采用固体绝缘材料为主绝缘介质及导电连接、隔离开关、接地开关、主母线、分支 母线等主导电回路单一或组合后用固体绝缘介质包覆封装为一个或几个具有一定功能、可再次组合或扩展的具备全绝缘、全 密封性能的模块。

环网单元适用于3~12KV/24KV/35KV、50Hz/60Hz的三相交流配电系统,用于环网供电或终端供电。环网单元可安装在工矿企业、住宅 小区、学校、公园等的配电系统,也可装入紧凑式型箱式变电站中,用于配电变压器的控制和保护。所以户内、户外型环 网单元均实现配电自动化。

本系列环网柜符合

IEC62271-1-2007《高压开关设备和控制设备第一部分:通用规范》

IEC620071-200-2003《1~52KV交流金属封闭开关设备和控制设备》

GB3906-2006《3.6~40.5KV交流金属封闭开关设备和控制设备》

GB/T11022-2011 《高压开关设备和控制设备标准的共用技术条件》

GB1984-2014《高压交流断路器》

GB1985-2014《高压交流隔离开关和接地开关〉

GB3804-2004《3.6KV~40.5KV高压交流负荷开关》

DL/T404-2007《3.6KV~40.5KV交流金属封闭开关设备和控制设备》

DL/T593-2016 «高压开关设备和控制设备标准的共用技术条件》

Q/GDW730-2012 《12KV固体绝缘环网柜技术条件》

DL/T402-2016《高压交流断路器》标准,

Product code of manufacturer

NKGT(XGN口-12)口

NKGT产品企业代号

X箱型 Cubicle Type

G固定式 Fixde Type

N户内 Indoor

口设计序号 Design Series

12/24/35额定电压kV Rated Voltage

口组合方案(V、F、C、D)

Combination Scheme

V: 真空断路器单元

V: VCB unit

F: 负荷开关熔断器组合单元

F : LBS-Fuse combination unit

C: 负荷开关单元

C: LBS unit

D: 直接进出线单元

D: in & Out Directly unit

( 二) .正常使用条件及技术参数

环境温度:最高+60℃, 不低于-40℃

环境湿度:相地湿度日平均不大于95%,月平均不大于90%

海拨高度:不超过2000米

地震烈度;不超过8度

没有火灾、爆炸危险、化学腐蚀及剧烈震动场所

Normal service conditions

Ambient temperature: highest + 60℃, lowest in - 40℃

Environmental humidity: average daily do not more than 95%, average monthly do not more than 90%

Altitude :Not more than 1000 meters

Seismic intensity : Not more than 8 degrees

No fire and explosion danger, no chemical corrosion and violent vibration places

|

序号

RF

|

环网柜主要技术参数

名称 Parameter

|

单位

Unit

|

参数Value

|

|

|

|

|

C mod

|

F mod

|

Vmod

|

D mod

|

|

1

|

额定电压 Rated voltage

|

KV

|

12

|

|

2

|

额定

绝缘水平

Rated insulating level

|

工频耐压(1min)

Power Frequency withstand voltage(1min.)

|

相间,相对地

Between phase,phase to earth

|

KV

|

42

|

42

|

42

|

42

|

|

3

|

|

|

断口Across the opened break

|

KV

|

48

|

48

|

48

|

48

|

|

4

|

|

雷电冲击耐压(峰值)

LightningWithstand Voltage(peak)

|

相间,相对地

Between phase,phase to earth

|

KV

|

75

|

75

|

75

|

75

|

|

5

|

|

|

断口 Across the opened break

|

KV

|

85

|

85

|

85

|

85

|

|

6

|

额定频率 Rated frequency

|

Hz

|

50

|

|

7

|

额定电流 Rated current

|

A

|

630

|

125

|

630

|

630

|

|

8

|

额定转移电流 Rated transfer current

|

A

|

|

3700

|

|

|

|

9

|

额定短路开断电流 Rated short circuit breaking current

|

KA

|

|

31.5

|

25

|

|

|

10

|

额定短路关合电流 Rated making current (E2)

|

KA

|

50(3次)

|

50

|

50

|

|

|

11

|

额定短时耐受电流(负荷/接地开关)

Rated shortime withstand current (LBS/ES)

|

KA

|

25

|

25

|

25

|

25

|

|

12

|

额定短路持续时间(负荷/接地开关)

Rated short circuit duration (LBS/ES)

|

s

|

4

|

4

|

4

|

4

|

|

13

|

额定峰值耐受电流(负荷/接地开关)

Rated peak withstand current(LBS/ES)

|

KA

|

50

|

50

|

50

|

50

|

|

14

|

额定短路关合电流 (接地开关)Rated making current(ES)

|

KA

|

50

|

|

|

15

|

额定机械寿命(负荷开关)Rated mechanincal life(LBS)

|

次times

|

3000

|

10000(VCB)

(断路器)

|

|

16

|

额定机械寿命(接地开关)Rated mechanincal life(ES)

|

次times

|

3000

|

|

|

17

|

额定

开断电流

Rated breaking current

|

闭环开断电流Breaking current of close loop

|

A

|

630

|

|

|

|

|

|

|

有功负载开断电流

Breaking current of active power

|

A

|

630

|

|

|

|

|

|

|

电缆充电开断电流

Breaking current of cable charging

|

A

|

10

|

|

|

|

|

18

|

触头开距 Contact opening distance

|

mm

|

9±1

|

|

9±1

|

|

|

19

|

超行程 Overtravel

|

mm

|

3.0 ±0.5

|

|

3.0 ±0.5

|

|

|

21

|

相间中心距Center distance between phases

|

mm

|

130±1.5

|

|

130±1.5

|

|

|

22

|

主回路电阻Main circuit resistance (不含熔断器)

|

μΩ

|

≦350

|

≦750

|

≦350

|

|

|

23

|

合闸时间 Closing time

|

ms

|

≦10000

|

|

25-60

|

|

|

24

|

分闸时间 Opening time

|

ms

|

17-45

|

|

17-45

|

|

|

25

|

平均合闸速度

|

m/s

|

|

|

0.9±0.2

|

|

|

26

|

平均分闸速度

|

m/s

|

1.3±0.2

|

|

1.3±0.2

|

|

|

27

|

三相不同期性

|

ms

|

≦2

|

|

≦2

|

|

|

28

|

二次回路1min工频耐压

Power frequency withstand voltage on secondary circuit(1 min.)

|

KV

|

2

|

|

29

|

负荷开关短路关合电流操作循环次数

Operation cycle times for short circuit making current of LBS

|

次

times

|

3(E2级) 3(E2 class)

|

|

30

|

局部放电Partial discharge

|

PC

|

≦20(1.2Ur下测量)

measured at 1.2ur

|

|

31

|

柜体防护等级

Protetcion class of cubicle body

|

|

IP4X

|

|

|

柜体及外壳防护等级

Protetcion class of the shell

|

|

IP67

|

|

序号

RF

|

环网柜主要技术参数

名称 Parameter

|

单位

Unit

|

参数Value

|

|

|

|

|

C mod

|

F mod

|

Vmod

|

D mod

|

|

1

|

额定电压 Rated voltage

|

KV

|

24

|

|

2

|

额定

绝缘水平

Rated insulating level

|

工频耐压(1min)

Power Frequency withstand voltage(1min.)

|

相间,相对地

Between phase,phase to earth

|

KV

|

64

|

64

|

64

|

64

|

|

3

|

|

|

断口Across the opened break

|

KV

|

79

|

79

|

79

|

79

|

|

4

|

|

雷电冲击耐压(峰值)

LightningWithstand voltage(peak)

|

相间,相对地

Between phase,phase to earth

|

KV

|

125

|

125

|

125

|

125

|

|

5

|

|

|

断口

Across the opened break

|

KV

|

145

|

145

|

145

|

145

|

|

6

|

额定频率 Rated frequency

|

Hz

|

50

|

|

7

|

额定电流 Rated current

|

A

|

630

|

125

|

630

|

630

|

|

8

|

额定转移电流 Rated transfer current

|

A

|

|

3700

|

|

|

|

9

|

额定短路开断电流 Rated short circuit breaking current

|

KA

|

|

31.5

|

25

|

|

|

10

|

额定短路关合电流 Rated making current (E2)

|

KA

|

50(3次)

|

50

|

50

|

|

|

11

|

额定短时耐受电流(负荷/接地开关)

Rated shortime withstand current (LBS/ES)

|

KA

|

25

|

25

|

25

|

25

|

|

12

|

额定短路持续时间(负荷/接地开关)

Rated short circuit duration (LBS/ES)

|

s

|

4

|

4

|

4

|

4

|

|

13

|

额定峰值耐受电流(负荷/接地开关)

Rated peak withstand current(LBS/ES)

|

KA

|

50

|

50

|

50

|

50

|

|

14

|

额定短路关合电流 (接地开关)Rated making current(ES)

|

KA

|

50

|

|

|

15

|

额定机械寿命(负荷开关)Rated mechanincal life(LBS)

|

次times

|

3000

|

10000(VCB)

(断路器)

|

|

16

|

额定机械寿命(接地开关)Rated mechanincal life(ES)

|

次times

|

3000

|

|

|

17

|

额定

开断电流

Rated breaking current

|

闭环开断电流Breaking current of close loop

|

A

|

630

|

|

|

|

|

|

|

有功负载开断电流

Breaking current of active power

|

A

|

630

|

|

|

|

|

|

|

电缆充电开断电流

Breaking current of cable charging

|

A

|

10

|

|

|

|

|

18

|

触头开距 Contact opening distance

|

mm

|

12±1

|

|

12±1

|

|

|

19

|

超行程 Overtravel

|

mm

|

3.0 ±1

|

|

3.0 ±1

|

|

|

21

|

相间中心距Center distance between phases

|

mm

|

380±1.5

|

|

380±1.5

|

|

|

22

|

主回路电阻Main circuit resistance

|

μΩ

|

≦350

|

≦750

(不含熔断器)

|

≦350

|

|

|

23

|

合闸时间 Closing time

|

ms

|

≦10000

|

|

25-80

|

|

|

24

|

分闸时间 Opening time

|

ms

|

23-50

|

|

23-50

|

|

|

25

|

平均合闸速度

|

m/s

|

|

|

0.5~0.9

|

|

|

26

|

平均分闸速度

|

m/s

|

1.1~1.7

|

|

1.1~1.7

|

|

|

27

|

三相不同期性

|

ms

|

≦2

|

|

≦2

|

|

|

28

|

二次回路1min工频耐压

Power frequency withstand voltage on secondary circuit(1 min.)

|

KV

|

2

|

|

29

|

负荷开关短路关合电流操作循环次数

Operation cycle times for short circuit making current of LBS

|

次

times

|

3(E2级) 3(E2 class)

|

|

30

|

局部放电Partial discharge

|

PC

|

≦20(1.2Ur下测量)

measured at 1.2ur

|

|

31

|

柜体防护等级

Protetcion class of cubicle body

|

|

IP4X

|

|

|

柜体及外壳防护等级

Protetcion class of the shell

|

|

IP67

|

|

序号

RF

|

环网柜主要技术参数

名称 Parameter

|

单位

Unit

|

参数Value

|

|

|

|

|

C mod

|

F mod

|

Vmod

|

D mod

|

|

1

|

额定电压 Rated voltage

|

KV

|

35

|

|

2

|

额定

绝缘水平

Rated insulating level

|

工频耐压(1min)

Power frequency withstand voltage(1min.)

|

相间,相对地

Between phase,phase to earth

|

KV

|

95

|

95

|

95

|

95

|

|

3

|

|

|

断口Across the opened break

|

KV

|

110

|

110

|

110

|

110

|

|

4

|

|

雷电冲击耐压(峰值)

lightningWithstand voltage(peak)

|

相间,相对地

Between phase,phase to earth

|

KV

|

185

|

185

|

185

|

185

|

|

5

|

|

|

断口

Across the opened break

|

KV

|

215

|

215

|

215

|

215

|

|

6

|

额定频率 Rated frequency

|

Hz

|

50

|

|

7

|

额定电流 Rated current

|

A

|

630

|

125

|

630

|

630

|

|

8

|

额定转移电流 Rated transfer current

|

A

|

|

3700

|

|

|

|

9

|

额定短路开断电流 Rated short circuit breaking current

|

KA

|

|

31.5

|

25

|

|

|

10

|

额定短路关合电流 Rated making current (E2)

|

KA

|

50(3次)

|

50

|

50

|

|

|

11

|

额定短时耐受电流(负荷/接地开关)

Rated shortime withstand current (LBS/ES)

|

KA

|

25

|

25

|

25

|

25

|

|

12

|

额定短路持续时间(负荷/接地开关)

Rated short circuit duration (LBS/ES)

|

s

|

4

|

4

|

4

|

4

|

|

13

|

额定峰值耐受电流(负荷/接地开关)

Rated peak withstand current(LBS/ES)

|

KA

|

50

|

50

|

50

|

50

|

|

14

|

额定短路关合电流 (接地开关)Rated making current(ES)

|

KA

|

50

|

|

|

15

|

额定机械寿命(负荷开关)Rated mechanincal life(LBS)

|

次times

|

3000

|

10000(VCB)

(断路器)

|

|

16

|

额定机械寿命(接地开关)Rated mechanincal life(ES)

|

次times

|

3000

|

|

|

17

|

额定

开断电流

Rated breaking current

|

闭环开断电流Breaking current of close loop

|

A

|

630

|

|

|

|

|

|

|

有功负载开断电流

Breaking current of active power

|

A

|

630

|

|

|

|

|

|

|

电缆充电开断电流

Breaking current of cable charging

|

A

|

10

|

|

|

|

|

18

|

触头开距 Contact opening distance

|

mm

|

22±1

|

|

22±1

|

|

|

19

|

超行程 Overtravel

|

mm

|

5 ±1

|

|

5 ±1

|

|

|

21

|

相间中心距Center distance between phases

|

mm

|

710±1.5

|

|

710±1.5

|

|

|

22

|

主回路电阻Main circuit resistance

|

μΩ

|

≦350

|

≦750

(不含熔断器)

|

≦350

|

|

|

23

|

合闸时间 Closing time

|

ms

|

≦10000

|

|

≦145

|

|

|

24

|

分闸时间 Opening time

|

ms

|

≦70

|

|

≦70

|

|

|

25

|

平均合闸速度

|

m/s

|

|

|

0.7±0.2

|

|

|

26

|

平均分闸速度

|

m/s

|

1.5±0.2

|

|

1.5±0.2

|

|

|

27

|

三相不同期性

|

ms

|

≦2

|

|

≦2

|

|

|

28

|

二次回路1min工频耐压

Power frequency withstand voltage on secondary circuit(1 min.)

|

KV

|

2

|

|

29

|

负荷开关短路关合电流操作循环次数

Operation cycle times for short circuit making current of LBS

|

次

times

|

3(E2级) 3(E2 class)

|

|

30

|

局部放电Partial discharge

|

PC

|

≦20(1.2Ur下测量)

measured at 1.2ur

|

|

31

|

柜体防护等级

Protetcion class of cubicle body

|

|

IP4X

|

|

|

柜体及外壳防护等级

Protetcion class of the shell

|

|

IP67

|

熔断器与变压器选型表

固体绝缘环网柜NKGTXGN15 具有以下显著特点:

与真空负荷开关组合.转移电流可达3150A:

全系列配变保护.最大熔芯电流可达200A:

双重的接地保护.可靠的五防联锁.安全性能更高;

选用标准熔断器.方便用户备品备件。

|

变压器初级电压Transformer primary Voltage (kV)

|

|

变压器额定容量(KVA)Rated capacity of transformer (kVA)

|

|

|

25

|

50

|

75

|

100

|

125

|

160

|

200

|

250

|

315

|

400

|

500

|

630

|

800

|

1000

|

1250

|

1600

|

|

3

|

熔断器

额定电流Fuse rated current

(A)

|

16

|

20

|

31.5

|

40

|

50

|

50

|

63

|

80

|

100

|

125

|

160

|

|

|

|

|

|

|

3.3

|

10

|

20

|

25

|

40

|

40

|

40

|

63

|

80

|

80

|

125

|

125

|

160

|

|

|

|

|

|

6

|

6

|

16

|

20

|

25

|

25

|

31.5

|

40

|

50

|

50

|

63

|

80

|

100

|

125

|

160

|

|

|

|

10

|

6

|

10

|

10

|

16

|

20

|

25

|

25

|

31.5

|

40

|

50

|

50

|

63

|

80

|

100

|

125

|

|

|

11

|

6

|

10

|

10

|

16

|

20

|

20

|

25

|

25

|

40

|

40

|

50

|

50

|

63

|

80

|

100

|

125

|

安全与保护

隔离刀可视断口 柜前有明显的隔离断口可视窗口,可查看隔离合位、隔离分位、 接地合位.三个工作位置,非常方便。

泄压设计 内部燃弧压力阀:当产品内部出现燃弧.会从该压力释放阀 释放压力.燃弧排至电缆沟,以免误伤操作人员。

绿色环保 设计不使用SF6气体作为灭弧介质及绝缘.对环境没有污染,一次回路采用少接点设计.确保运行期间低能耗。

应用领域

低温寒冷地区:无SF6气体应用.无需考虑SF6气体低温运行问题.在-45°C下也能正常运行。

高原地区:无需考虑高原大气压对绝缘性能的影响。

强风沙地区:密体绝缘环网柜本体安全防护等级IP67.控制回路室采用特殊处理确保强风沙地区长期运行。

沿海潮湿地区:环氧树脂密封.抗潮湿.抗盐雾腐蚀.确保在沿海地区能长期使用。

高环保要求地区:SF6气体对大气暖化影响已经高度引起重视,固体环网柜取消了SF6气体,对环境和人身无任何汚染和伤害。

智能电网中:由于主开关都能实现电动.选配本公司研发的智能控制器.可对开关设备和变电站现场进行遥控、 遥测、遥信.既能进行分散控制.又能方便集中控制。

Safety and protection

In front of the disconnector visual fracture cabinet, there is an obvious isolation fracture visual window, which can view the isolation closing position, isolation opening position and grounding closing position. It is very convenient.

Pressure relief design internal arc pressure valve: when there is arcing in the product, the pressure will be released from the pressure relief valve. The arc will be discharged to the cable trench to avoid accidental injury to operators.

The green design does not use SF6 gas as arc extinguishing medium and insulation. It has no pollution to the environment. The primary circuit adopts less contact design to ensure low energy consumption during operation.

application area

Low temperature and cold area: there is no SF6 gas application. It does not need to consider the low temperature operation of SF6 gas. It can also operate normally at - 45 ° C.

Plateau area: no need to consider the influence of Plateau Atmospheric Pressure on insulation performance.

Strong wind and sand area: dense insulation ring main unit body safety protection grade is IP67. Special treatment is adopted in control circuit room to ensure long-term operation in strong wind and sand area.

Coastal humid area: epoxy resin sealing, moisture resistance, salt spray corrosion resistance, to ensure long-term use in coastal areas.

Areas with high environmental protection requirements: the impact of SF6 gas on atmospheric warming has been highly valued, and SF6 gas has been cancelled in solid ring main unit, which has no pollution and damage to the environment and human body.

In the smart grid: since the main switch can be electrically operated, the intelligent controller developed by our company can be used for remote control, telemetry and remote signaling of the switchgear and substation site. It can not only carry out decentralized control, but also facilitate centralized control.

固体绝缘环网柜机芯结构特点 Structural characteristics of solid insulated ring main unit

真空灭弧室 Vacuum interrupter

真空断路器具有开断短路电流能力.用于电路和电气设备的过载和短路保护。因其触头开距小.燃弧时间短. 触头一开断故障电流时烧伤轻微.所需的操作能量小.动作快等特点.它同时还具有体积小.重量轻.维护工作量小.能防火、防爆,操作噪声小的优点.是替代油断路器和SF6断路器的理想断路器.广泛用于电力、冶金、通迅等 行业的高频加热等配电系统。断路器用真空灭弧室是真空断路器的关键部件.是真空断路器的心脏.它基本上决定 了断路器的主要性能。

固体绝缘系统

采用APG工艺成型的固封极柱将真空灭弧室和上下出线座等载流导体封装成一个整体。隔离开关安装在固封极柱的腔体内,使得相间绝缘以固体绝缘方式为主绝缘方式。单相间绝缘母线设计.避免相间及对地等严重故障的发生。母线可扩展设计.实现功能单元无限扩展。

三工位刀闸

所有开关柜配有三工位刀闸。三工位刀闸与主开关一同内置于固封极柱内。三相联动.可操作实现工作/隔离/接 地三个位置。与主开关采用了机械联锁,只有在主开关处于分闸位置时.三工位刀闸才能动作。

Vacuum circuit breaker has the ability of breaking short-circuit current. It is used for overload and short-circuit protection of circuit and electrical equipment. It has the advantages of small volume, light weight, small maintenance workload, fire prevention, explosion-proof and low operation noise. It is an ideal circuit breaker to replace oil circuit breaker and SF6 circuit breaker. It is widely used in power, metallurgy, communication, etc High frequency heating and other distribution systems in the industry. Vacuum interrupter for circuit breaker is the key component of vacuum circuit breaker and the heart of vacuum circuit breaker. It basically determines the main performance of circuit breaker.

Solid insulation system

The current carrying conductors, such as vacuum interrupter and upper and lower outlet sockets, are packaged as a whole by the solid sealing pole formed by APG process. The disconnector is installed in the cavity of the fixed pole, so that the phase to phase insulation is mainly solid insulation. Single phase insulated bus design can avoid serious faults such as phase to phase and ground. Bus expandable design. Realize unlimited expansion of function unit.

Three position knife switch

All switch cabinets are equipped with three position knife switch. The three position knife switch and the main switch are built into the fixed pole. Three phase linkage. It can be operated to realize three positions of work / isolation / grounding. Mechanical interlock is adopted with the main switch. Only when the main switch is in the opening position, the three position knife switch can act.

操作机构

断路器操作机构为弹簧操作机构.有着结构简单、动作可靠、体积小巧、免维护等特点.合闸功大小可根据用 户要求上下调整.机构可以手动储能、手动合闸、手动分闸.也可以电动储能、电动分合闸.方便用户操作。

三工位刀闸操作机构釆用过中弹簧设计.能快分快合.具有开断和关合一定负荷电流的功能.三工位机构除了 能手动操作外.还能进行电动操作.可实现智能远程控制隔离与接地.大大方便了用户的使用。

固体绝缘环网柜是一种小型的开关柜,其结构如下:

a.高压负荷开关和高压带电部件密封在无任何气体的环氧树脂绝缘套筒売内,真空灭弧室灭弧.体枳小灭弧可靠,负荷开关带接地开关.有合、分闸和接地三个工位,接地刀并且有隔离刀的功能。

b.可随意组合.每路单元均通过三个高压套管出线,电缆连接方便。

c.采用进口制成的密封箱体,操作机构连接处和高压套管处采取了严格的密封措施性能良好。

d.釆用APG工艺由进口环氧树脂制成的高压套管及高压绝缘筒.绝缘筒和高压套管之间通过硅橡胶套紧配合装配而成.有较好的密封作用。

e.各路装有相互独立的操作机构.机构安装在柜体的前面上,具有多种机械联锁功能。

f.负荷开关和接地开关装有弹簧操动机构.负荷开关可以手动或电动操作,接地开关不但有接地作用而且也有隔离作用.只能手动操作。

g断路器可以配置永磁操动机构.可以电动合分闸.可以手动分闸.但不能手动合闸。断路器也可以装弹簧机构. 即可手动也可电动.预留配电自动化接口。

h.环网柜面板上有可视窗,能最直接观察到隔离刀断口的分合状态.有明显断开点。

i每个环网柜单元都有三个单独的绝缘筒并列而成.安装方便.容易更换最大的优点是避免了相间放电。

j固体绝缘全封闭环网柜主要部件是由绝缘筒和真空灭弧室组成。

k. 固体绝缘材料采用进口环氧树脂.厚度不小于10mm.具有较强的抗腐蚀能力.较高的绝缘能力.内部空间大于 150mm.相与相之间单独分开并通过底板安装架连接在一起.组合灵活结构简单合理.美观。

l.箱体表面无紧固件可供拆卸.防盗性好.箱体具有IP33的防护等级.防雨性能好。

m顶盖设有通风□・进风口在箱体下部.并有防尘过滤网.出风□设在箱体顶部,并隐藏在房槽下面形成自下而 上的空气对流.使箱体具有良好的隔热与通风效果.而盖设有一定角度的排水倾角。

n.箱体有电缆进线口的密封式地板.防止电缆沟内的潮r进入箱体。

o门以密封条密封.门锁为防雨式结构,门打开时有限位拉杆使门便于固定。

P箱体内开关为固体绝缘全密封结构.不需要加热器.电缆头根据用户要求可分可触摸和不可触摸型.不怕浸水。

操动机构与操作

a环网单元中的各路负荷开关和接地开关装有相互独立的弹簧操动机构.装在柜前面板上.可以手动散电动操

作。面板上每路有两个操作孔.分别操作负荷开关和接地开关。真空断路器配有一体式的永磁操作机构和弹簧操作 机构。

b负荷开关操作说明

送电操作

先合隔离接地开关:将操作手柄插入接地操作孔(在隔离刀处于接地合闸状态时)・逆时针旋转,接地分闸.

再将操作手柄插入隔离操作孔内.逆时针旋转.合上隔离刀。

再合负荷开关:将操作手柄插入主开关操作孔内.逆时针转动2圈左右.主开关合闸。

停电操作

先分负荷开关:逆时针转动分闸旋扭.开关分闸。

再分隔离接地开关:将操作手柄插入隔离机构操作孔.顺时针旋转,分开隔离刀.再将操作手柄插入接地操作

孔内.顺时针旋转.合上接地。

c断路器操作说明

d机械联锁:负荷开关、断路器和接地开关间有机械联锁。当负荷开关、断路器在合闸状态,接地开关不能分、

合闸:接地开关在合闸状态,负荷开关、断路器不能分、合闸。

e.熔断器的安装和更换

(1)先闭合接地开关。

(2)把操作把手用力提起,逆时针旋转,使销子出槽

(3)把撞针机构装入熔丝桶,使销子处于槽内,顺时针旋转.使操作把手平行于面板,然后用力压下把手即可。

(4)当负荷开关接地时才能打开。

Operating mechanism

The operating mechanism of the circuit breaker is a spring operating mechanism. It has the characteristics of simple structure, reliable action, small size and maintenance free. The closing power can be adjusted up and down according to the user's requirements. The mechanism can be manually stored energy, manually closed and manually opened. It can also be electric energy storage and electric opening and closing, which is convenient for users to operate.

The operating mechanism of three position knife switch adopts the design of through spring. It can quickly open and close. It has the function of breaking and closing certain load current. Besides manual operation, it can also carry out electric operation. It can realize intelligent remote control isolation and grounding, which greatly facilitates the use of users.

Solid insulated ring main unit is a kind of small switch cabinet, its structure is as follows:

A. High voltage load switch and high voltage live parts are sealed in epoxy resin insulating sleeve without any gas. The vacuum interrupter is small in size and reliable in arc extinguishing. The load switch is equipped with grounding switch. It has three positions of closing, opening and grounding. The grounding knife has the function of isolating knife.

B. It can be combined at will. Each unit is led out through three high voltage bushing, so the cable connection is convenient.

C. The imported sealing box is adopted, and strict sealing measures are adopted at the connection of operating mechanism and high-voltage bushing, and the performance is good.

D High voltage bushing and high-voltage insulating cylinder made of imported epoxy resin are adopted in APG process. The insulating cylinder and high-voltage bushing are assembled with silicone rubber sleeve and have good sealing effect.

E Each channel is equipped with independent operating mechanism. The mechanism is installed on the front of the cabinet body and has a variety of mechanical interlocking functions.

F Load switch and grounding switch are equipped with spring operating mechanism. Load switch can be operated manually or electrically. Grounding switch not only has grounding function, but also has isolation function. It can only be operated manually.

G. the circuit breaker can be equipped with permanent magnet operating mechanism. It can be electrically closed and opened. It can be opened manually, but it can not be closed manually. The circuit breaker can also be equipped with spring mechanism, which can be manual or electric. The interface of distribution automation is reserved.

H. There is a visual window on the panel of the ring main unit, which can directly observe the opening and closing state of the disconnector fracture, and there are obvious breaking points.

I each RMU unit is composed of three separate insulating cylinders in parallel. It is easy to install and replace. The biggest advantage is to avoid phase to phase discharge.

J. the main components of solid insulation fully enclosed ring main unit are composed of insulating cylinder and vacuum interrupter.

K The solid insulation material is imported epoxy resin. The thickness is not less than 10 mm. It has strong corrosion resistance and high insulation capacity. The internal space is more than 150 mm. The phases are separated separately and connected together through the base plate mounting frame. The combination is flexible, the structure is simple, reasonable and beautiful.

L. There is no fastener on the surface of the box for disassembly. It has good anti-theft property. The box has the protection grade of ip33 and good rain proof performance.

M The top cover is equipped with ventilation . The air inlet is located at the lower part of the box body, and dust-proof filter screen is set. The air outlet is set at the top of the box and hidden under the room slot to form air convection from bottom to top. The box has good heat insulation and ventilation effect. The cover is provided with a certain angle of drainage angle.

N. The box has a sealed floor with cable inlet to prevent moisture in the cable trench from entering the box.

O the door is sealed with sealing strip. The door lock is rainproof structure, and the limited pull rod makes the door easy to fix when the door is opened.

P The switch in box is of solid insulation and fully sealed structure. There is no need for heater. The cable head can be divided into touch type and non touch type according to the user's requirements. It is not afraid of immersion.

Operating mechanism and operation

A. each load switch and grounding switch in the ring network unit are equipped with independent spring operating mechanism. They are installed on the front panel of the cabinet, and can be operated manually make. There are two operation holes on the panel for operating load switch and grounding switch respectively. Vacuum circuit breaker is equipped with integrated permanent magnet operating mechanism and spring operating mechanism.

B. operating instructions of load switch power transmission operation

First close the isolating grounding switch: insert the operating handle into the grounding operation hole (when the disconnector is in the grounding closing state) · rotate counterclockwise to open the grounding

Then insert the operating handle into the isolation operation hole. Turn it anticlockwise to close the isolating knife.

Re closing the load switch: insert the operating handle into the operation hole of the main switch. Turn it about 2 times anticlockwise to close the main switch.

Blackout operation

First open load switch: turn the opening knob anticlockwise to open the switch.

Then open the isolation grounding switch: insert the operating handle into the operating hole of the isolation mechanism. Rotate it clockwise to separate the isolating knife, and then insert the operating handle into the grounding operation

Inside the hole. Rotate clockwise. Close the grounding.

C operating instructions of circuit breaker

D mechanical interlocking: there is mechanical interlocking between load switch, circuit breaker and grounding switch. When the load switch and circuit breaker are in the closing state, the grounding switch cannot be opened

Closing: grounding switch is in closing state, load switch and circuit breaker cannot be opened or closed.

E. Installation and replacement of fuses

(1) Close the grounding switch first.

(2) Lift the handle and rotate it anticlockwise to make the pin out of the groove

(3) Install the striker mechanism into the fuse barrel, make the pin in the slot, rotate clockwise, make the operation handle parallel to the panel, and then press down the handle with force.

(4) It can only be opened when the load switch is grounded.

结构示意图 Structure diagram

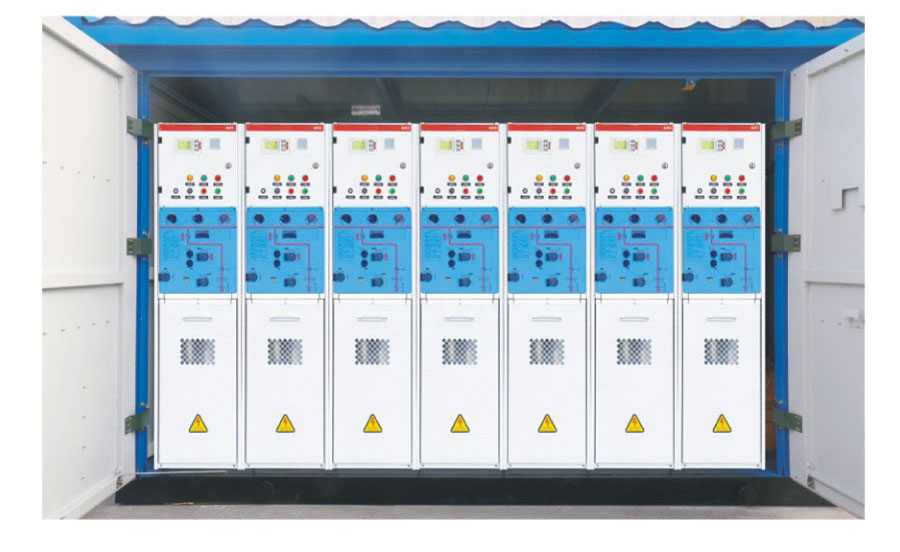

产品外观展示Product appearance display

户内型环网单元的柜体结构如图示 The cabinet structure of indoor ring network unit is shown in the figure

户外型环网单元的柜体结构如图示The cabinet structure of outdoor ring network unit is shown in the figure

安装及尺寸图Installation

●开关设备安装基础的施工应符合《电力建设施工及验收技术规范》中的有关条款规定

The foundation for cubicle should be in conformance with relative requirements stipulated in《The code of erection and

acceptance of electric power construction》

●柜体单列时,柜前走廊以1.5米为宜:双列布置时,柜间操作通道走廊以2米为宜

The corridor width in front of cubicles arranged in one row takes l.5m properly, and 2m proper for double rows arrangement

●一次电缆终端安装严格按相关工艺要求

The fitting of primary cable teerminals should be strictly according to relevant technology requirements

●电缆沟上方预埋10号槽钢,柜子放在槽钢上固定

The No. 10 U steels built in the top edges of cable trench can be used as the base of cubicle

环网单元应安装在通风良好的地方.在正面操作和维护.环网单元的底座有地脚安装孔.在室内柜体可以离墙或 靠墙安装.安装位置如图示。安装地基上所铺设轨道的平面度.每平米范围不得超过2mm 环网单元的底座必须固 定在地基上。户外安装时地基要求建在较高地势处.四周离墙或遮挡物的距离不得小于1米.以免妨碍开门。坑壁用 水泥和实心砖砌制.表面作防渗水处理。坑壁及基础平台用1:2.5水泥沙浆面厚度为20mm.表面要平整。混泥土制 做按GB232-82《电气装置安装工程施工及验收规范》。电缆安装完成后.电缆室底板应进行密封处理.防止地沟潮气进入。环网单元的接地必须与现场的接地网相连。环网单元的接地处有接地标志。

The ring network unit shall be installed in a well ventilated place. It shall be operated and maintained in the front. The base of the ring network unit has anchor mounting holes. In the indoor cabinet, it can be installed away from or against the wall. The installation position is shown in the figure. The flatness of track laid on the installation foundation shall not exceed 2mm per square meter. The base of ring network unit must be fixed on the foundation. When installing outdoors, the foundation is required to be built at a higher terrain. The distance from the wall or shelter should not be less than 1 meter to avoid obstructing the door opening.

The pit wall is made of cement and solid brick, and the surface is treated with anti seepage. The thickness of 1:2.5 cement mortar for pit wall and foundation platform is 20 mm, and the surface shall be smooth. The concrete shall be made according to gb232-82 code for construction and acceptance of electrical installation engineering. After cable installation, the bottom plate of cable room shall be sealed to prevent moisture from entering trench. The grounding of ring network unit must be connected with the grounding grid on site. There are grounding marks at the grounding point of ring network unit.

订货时需确定的资料内容 The data needed for order

●一次线路系统图,排列图及平面布置图

Primary schame and the layout or the arrangement sketch.

●二次线路原理图,其中包括操作、信号、保护回路各电器元件的型号规格

Principle diagram of secondary circuit, including the type and the spec of electric components in operation, signal and

protection circuit.

●开关柜内电器元件的型号、规格、数量

The type, specification and quantity of primary components in the cubicle

●特殊环境条件下的要求

Special ambient condition

●附件及备件的种类和数量

The sorts and the quantity of accessories and spare parts.

●用户需要的特殊要求,订货时可以与制造厂协商

For special requirement, if any, please contact the manufacturer

地基图Foundation

说明:

1.基础施工上表面要水平,坑口边沿要预埋10#槽钢,预埋底架与混凝土面平或高出 1-2mm

2.需在电缆井旁边开一入口,以便人能进入电缆井.便于电缆安装。

3 L.S.H分别为户外箱长宽高

Explain:

1The upper surface of foundation construction shall be horizontal,

10 × 10 channel steel shall be embedded at the edge of the pit,

The embedded underframe shall be level or 1-2mm higher than the concrete surface

2. It is necessary to open an entrance beside the cable well, so that people can enter the cable well and facilitate cable installation.

3 L S H is the outdoor box length, width and height respectively

运输和储存

包装好的环网单元可用电动叉车或吊车搬运,环网单元上配备了吊环.供搬运时吊装之用。吊运用绳索不能短于2m。 环网单元在使用现场安装前应放在干燥、通风、无灰尘的地方。如用塑料袋覆盖.底部应敞开通风。

使用与维护

A 使用前的检查:环网单元在使用前.为了人身及设备安全.必须进行下列检查

-检查主电路和接地电路是否正确连接。

-检查机械联锁是否正确、可靠。

•检查环网单元内负荷开关和接地开关的操作是否灵活、正确。

•检査高压电缆的连接是否正确、可靠。

B .运行

•应按规定的操作顺序.使环网单元投入运行。

C.维护:本设备基于如下优点.不需要进行日常维护

•所有的带电部件均安装在环氧塑脂绝缘筒内。

•所有置于环氧塑脂绝缘筒外面的操作机构部件都已经进行了电镀处理。

•主轴用铜轴套支撑,就是不加润滑剂,也可以连续、有效地工作。

注意:若环网单元有故障.不要试图用钻孔机、切割机或其它工具打开环网单元修理.这些操作只能有本公司人员 负责。

随机文件和附件

产品出厂时.随机提供以下资料和附件:

•产品安装使用说明书。-产品岀厂试验报吿。•产品合格书。•装箱清单。-操作手柄。-其他附件。

Transportation and storage

The packaged ring network unit can be transported by electric forklift or crane. The ring network unit is equipped with lifting rings for lifting during transportation. The rope used for hoisting shall not be shorter than 2m. The ring network unit should be placed in a dry, ventilated and dust-free place before installation on site. If covered with plastic bags, the bottom should be open and ventilated.

Use and maintenance

A pre use inspection: before using the unit, the following inspections must be carried out for personal and equipment safety

-Check that the main circuit and the ground circuit are properly connected.

-Check whether the mechanical interlock is correct and reliable.

-Check whether the operation of load switch and grounding switch in ring network unit is flexible and correct.

-Check whether the connection of high voltage cable is correct and reliable.

B. Operation The ring network unit shall be put into operation according to the specified operation sequence.

C. Maintenance: the equipment is based on the following advantages. No routine maintenance is required

All live parts are installed in epoxy resin insulated cylinder.

All operating mechanism components outside the epoxy resin insulated cylinder have been electroplated.

The main shaft is supported by copper shaft sleeve, which can work continuously and effectively without lubricant.

Note: if there is a fault in the ring network unit, do not attempt to open the ring network unit for repair with drilling machine, cutting machine or other tools. These operations can only be carried out by our company's personnel.

Attached documents and attachments

When the product leaves the factory, the following data and accessories shall be provided with the machine:

Product installation and operation manual. -Test report of product delivery. Product qualification certificate.

packing list. -Operating handle. -Other attachments.